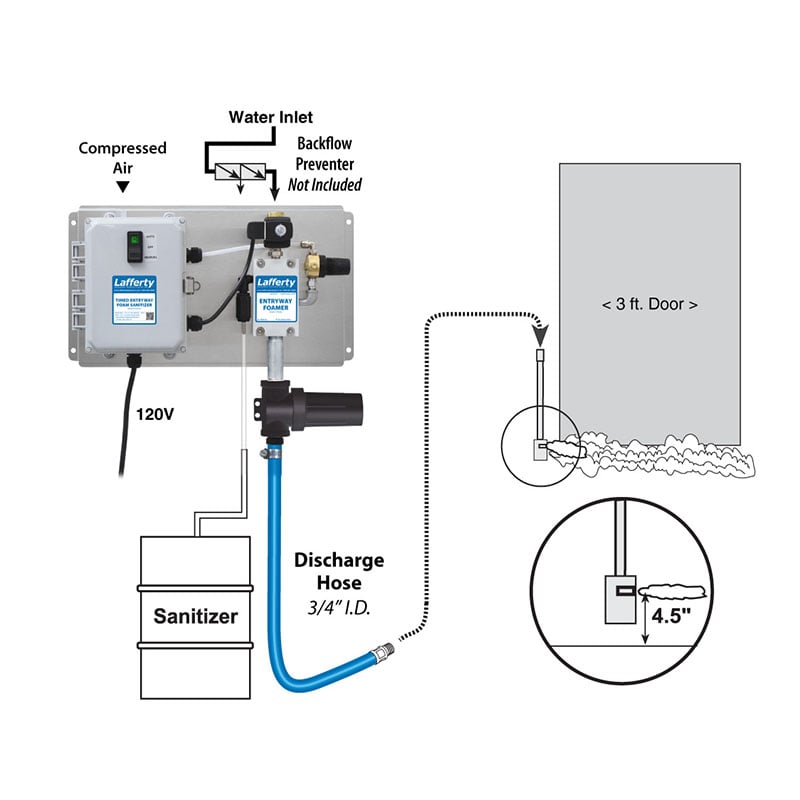

The Timed Entryway Foam Sanitizer is an automated foam applicator for projecting sanitizing chemicals on to floors of 3′ wide employee walk doors to prevent cross contamination. When activated, this venturi injection system uses city water pressure (35 – 125 PSI) to draw and blend chemical concentrate into the water stream to create an accurately diluted solution. Rich, clinging foam is created by injecting compressed air into the solution to greatly increase volume and coverage ability. Foam is then projected through the discharge hose and Spreader™ nozzle. The system timer is user-programmable to meet the needs of any facility.

Key Features

Applies a layer of rich, clinging foam to entryway floors to prevent cross-contamination

Designed for 3′ wide employee walk doors

Dilutes chemical concentrate “on-the-fly” from a container near the unit

The unique Spreader™ nozzle lays a foam pattern 3′ across and 4′ wide to ensure all foot traffic and cart wheels are fully exposed to the sanitizer

Automatic activation and shutoff for use in moderate to high traffic areas

Adjustable timer controls the application of foam at regular intervals – up to 1 minute foaming and up to 1 hour off

Adjustable foam consistency (wet/dry)

Chemical resistant wetted components ensure durability and years of reliable service with minimal maintenance